In the first place, I do not know why I am here. It was supposed to be my wife who was invited here. He encouraged me to attend the said Uratex tour and then after that, I will orient her how foams were made through the series of pictures that I captured.

She was not available by that time the tour was set-up and me, representing her just made her felt she also got a tour.

When I realized at the end, yes, my wife is right. How in the world foams were really made? I have reach in this age and did not know about it. So I was really fortunate to be included.

Press Release – History Behind URATEX:

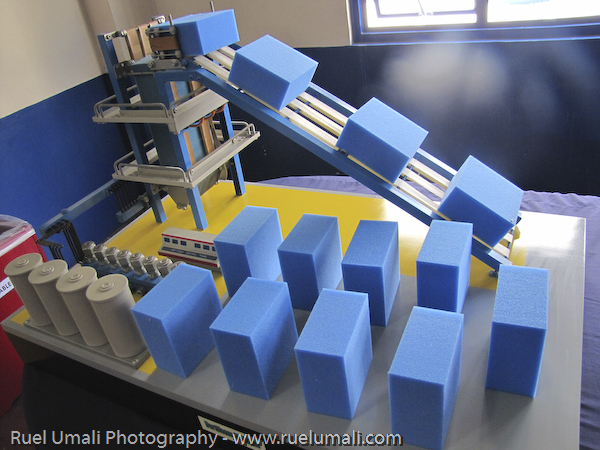

The RGC Group of Companies revolutionized foam making back in 1987 when they set up the first continuous foaming machine in the country called the “Vertifoam” process. This involves computerized metering of materials to form perfectly-shaped foam with lesser scrap that benefited both the market and the environment because of less wastage.

In 2001, the group further blazed the trail in foam-making when it installed new foaming equipment called “Hennecke.” Tagged as the “Mercedes Benz” of the foam-making industry, this German-manufactured equipment is regarded as the best in the world. On December 2009, the RGC Group invested on another Hennecke machine with the latest technological improvements to serve as back-up to the year 2001 version.

First we were oriented by Mr. Dindo, the General Manager who led us also with the plant tour. We were also given written materials to guide us but I will just simply it.

- Research and Development – responsible for developing formulation that will result to customers’ need. I thought foams were only use for bed. Their products expanded from car seats, footwear, garments and electronics.

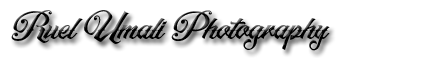

- Foaming – once it is finalized, now the production for foam will be ready controlled by machine’s computer system. Liquid will turn into cream, then solid foam.

- Curing area – long blocks are picked up and transferred to curing area. It will be started to cool down until it is ready for cutting.

- Foam block warehouse – where foams will be stored and from there, the plant’s production department will request for a specific type of block with different sizes as per orders coming from customers.

- Production area –foam blocks are cut into the requested size and then “contoured” based on the type of product to be produced, whether a pillow, a mattress, or even a car seat foam.

Here are the finished products:

Aside from the foam product, Uratex also got Monoblock’s tables/chairs and Ready-Wrap containers for storing, organizing, preparing and re-heating food hygenically that offer variety of sizes.

Is it obvious that after the tour we were all enjoyed the Uratex plant tour.

Truly, the actual knowledge you gain is a lot! Using those modern high tech state-of-the-art equipment of making a foam is already a worth-while educative escapade! Thanks Uratex for this experience.

For more information, visit their showroom: http://www.uratex.com.ph/where-to-buy/#uratexfactoryoutlets